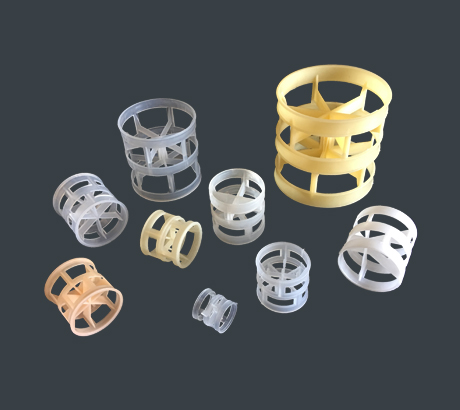

Which is better, random packing or structured packing, how do we choose, what are the differences? Here is a summary of some knowledge, and then for some friends who do not know the answer one by one:

This structure promotes the flow of gas and liquid, and the mass transfer performance of tower packing is mentioned. After that, it will bring more newly designed products, such as HY-Pak, Flexring and so on.

Raschig Ring

It is a bulk filler developed earlier, its height and outer diameter equal. Invented by German chemist Friedrich Rashig in 1914, it also marked the scientific orbit of the development of tower packing. However, in practical application, “wall flow, channel flow” and other phenomena often occur.

Cascade Mini Ring

It was developed by British company MTL Ltd, also known as CMR. It not only changes the traditional equal length and diameter, but also has a tapered flanging on one edge. This special structure shortens the distance of air passing through the wall, while also reducing the resistance of air passing through the bed and increasing the voidage.

Ralu Ring

This is an improved Bauer ring. The main improvements are increased turning over and wall thickness at both ends. The bed height can be reduced without changing the separation efficiency, thus reducing the pressure drop.

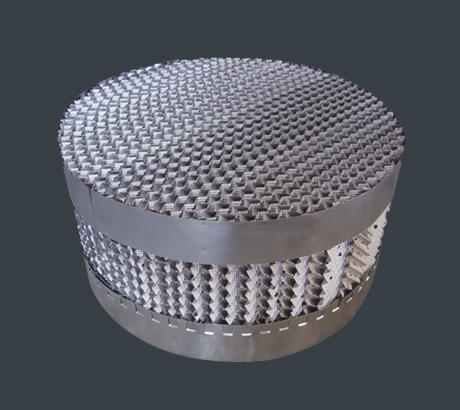

The price of structured packing and random packing is not the same, the purpose is not the same, if not from the price consideration, the structured parameters are better than the structured packing. But it is the same as the structured filler material, respectively: ceramic, metal, plastic. According to the different usage of different application fields, they are mainly used in petrochemical, chemical, chemical fertilizer industries, bulk filler and structured filler do not have to be used together, depending on the specific situation.

For the choice of filler, we should consider production capacity, efficiency, cost, pressure drop and other factors, the performance of the material should also be considered. Here are some basic factors to consider:

1, material: should be processed according to the performance of the material and the temperature of the operation to determine the material.

2. Size: there is a lower limit for the suitability of the tower diameter and packing outer diameter, which can be used as a reference. When the diameter ratio is lower than this value, it is difficult to predict their performance, so pay attention to it.

3. Passing ability: the passing ability of the packing refers to the air velocity of the empty tower at the liquid flooding point.

4. Pressure: the power consumption of the packed tower mainly depends on the total pressure drop of the whole tower in the gas phase.

5. Nature: There are many types of structured packing. If we focus on gas-liquid flow channel, we should make the gas-liquid distribution as uniform as possible.

6. Some focus on the expansion of the contact surface.

7. Some consider to reduce the resistance as far as possible, there are all kinds of parallel plate