Column tray is the main component structure in plate column, including tray (tray), drain pipe, overflow weir, various forms of valves, fasteners and supporting tray type supporting parts, etc. It is to meet the requirements of distillation, reaction and separation.

- Sieve Tray is uniformly opened many holes on the tray (gas does not detours). Has the following advantages:

1) Simple structure, convenient production and maintenance.

2) The production capacity under the same conditions is higher than the valve tower;

3) Tray pressure drop is low, suitable for vacuum operation;

4) The tray efficiency is higher, but slightly lower than the floating valve tower;

5) It has higher operating elasticity, slightly lower than bubble cover tray

But small aperture screen is easy to plug, not easy to deal with dirty materials, viscous and with solid particles of liquid.

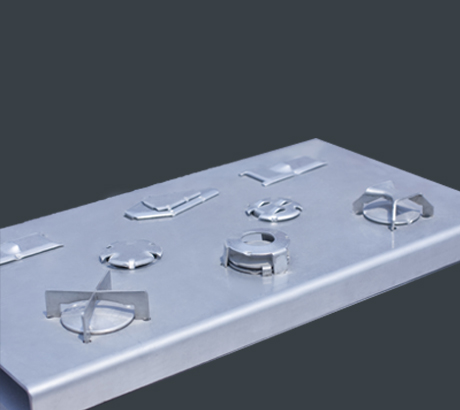

- Float valve tray This tray has two main categories: disk-shaped floating valve and strip floating valve. Figure 1-10 shows the main forms of floating valves. Figure 1-10 Main opening of a floating valve

A)PI type floating valve B)V-4 type floating valve C) T type floating valve

1) Disc float valve. The opening hole on the tray is a round hole, and the floating valve is a disc. The floating valve can be fixed with three legs and the cross to raise the position of the floating valve. The F1 type floating valve is fixed with three legs to raise the position of the floating valve.

2) Strip float valve. This kind of float valve is a long strip with ouleg in the tray to open a long hole, and some of the strip is one-sided on the hole or groove.

- Bubble Cap Tray is the earliest tray, in recent ten years due to the development of tower equipment many new towers.

1) The operation flexibility is large, and the efficiency is still high when the load varies widely.

2) The range of liquid gas ratio is large.

3) Not easy to plug.

4) Can be suitable and in a variety of media.

5) Stable and reliable operation.

Disadvantages: complex structure, high construction, inconvenient installation and maintenance, large gas pressure drop, lower efficiency than other tray.